Maple syrup is a delicious and versatile natural sweetener enjoyed for centuries. From drizzling it over pancakes to using it in marinades and desserts, maple syrup adds a rich and distinctive flavor to various dishes. But have you ever wondered how this sweet liquid is made? This article will dive deep into maple syrup production and explore the fascinating process of using a maple syrup evaporator. So grab a stack of pancakes, sit back, and let’s learn all about maple syrup evaporators!

What is Maple Syrup Evaporator?

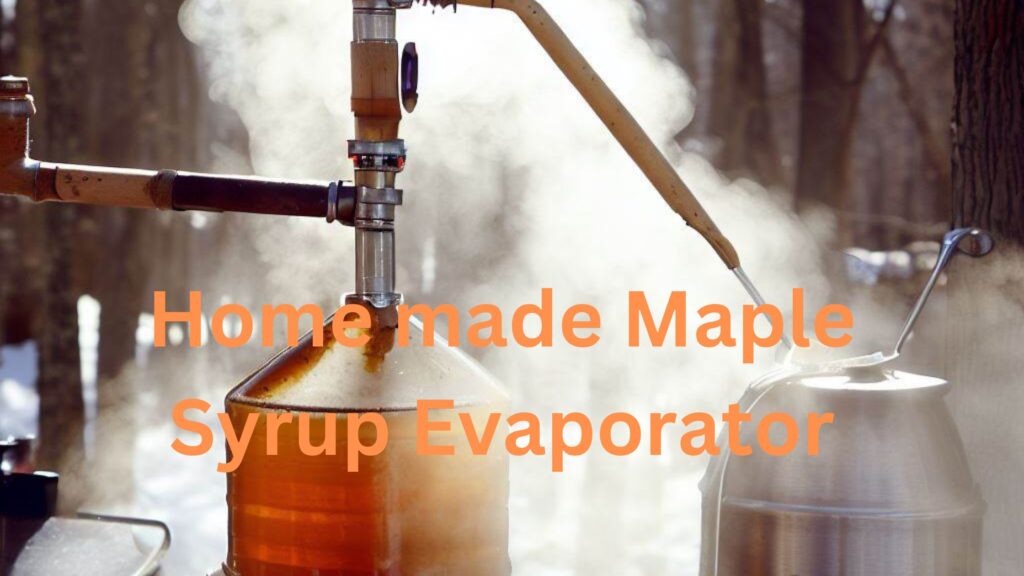

A maple syrup evaporator is a specialized equipment used to produce maple syrup. It is a large pan or set of pans designed to evaporate the excess water content from maple sap, leaving behind the concentrated maple syrup. Making maple syrup involves collecting sap from maple trees and boiling it to remove the water, resulting in the thick and sweet syrup we all know and love.

How does a Maple Syrup Evaporator work?

A maple syrup evaporator consists of a series of shallow pans or channels, often made of stainless steel or aluminum, placed over a heat source. The pans are divided into compartments, with each compartment being heated progressively. This allows the sap to flow from one compartment to another, gradually thickening and concentrating as it moves through the evaporator. The heat source, typically a wood fire or fuel burner, provides the energy needed to boil the sap and evaporate the water content.

The Process of Making Maple Syrup

Now that we understand the basics of a maple syrup evaporator let’s take a closer look at the step-by-step process of making maple syrup.

Tapping the Trees

The first step in maple syrup production is tapping the trees. This usually occurs in late winter or early spring when the weather conditions are right. A small hole is drilled into the trunk of a maple tree, and a spout or tap is inserted into the hole. This allows the sap to flow out of the tree and be collected.

Once the trees are tapped, the sap starts flowing. Sap collection involves hanging buckets or attaching tubing systems to the taps to catch the liquid as it drips out of the trees. The sap is collected in containers or transferred through the tubing into storage tanks for transportation to the sugarhouse.

After the sap is collected, it undergoes a filtration process to remove any impurities and debris that may be present. This is typically done by passing the sap through a series of filters, such as a mesh filter or a reverse osmosis system. Once filtered, the sap is preheated to raise its temperature before it enters the evaporator.

Evaporation and Concentration

The preheated sap is then transferred to the maple syrup evaporator. As the sap flows through the evaporator pans, the heat source underneath causes the water in the sap to evaporate. This process concentrates the sugars and flavors in the sap, gradually transforming it into maple syrup. The sap passes through multiple compartments, each heated to a higher temperature, ensuring efficient evaporation and concentration.

Finishing and Filtering

Once the sap reaches the desired sugar concentration, it is transferred to a finishing pan where the final evaporation stages occur. This ensures that the syrup has the perfect consistency and flavor. The syrup is carefully monitored for the desired density during this stage using a hydrometer. Once the correct thickness is reached, the syrup is filtered again to remove any remaining impurities, resulting in a smooth and precise finished product.

What is Maple Syrup Sap?

Maple syrup sap is the raw liquid extracted from maple trees, mainly from sugar maple, black maple, and red maple. It is the starting point for the production of maple syrup.

Maple sap is a clear and watery fluid that flows through the tree’s inner layers during the early spring months. It contains various dissolved minerals, nutrients, and sugars, which are essential for the growth and nourishment of the tree. The sap’s composition can vary slightly depending on tree species, geographic location, and environmental conditions.

The sap flows in the tree’s xylem vessels, transporting water and nutrients. During winter, the tree stores starch in its roots and trunk. When the temperatures rise above freezing during the spring, the tree converts these stored starches into sugars. This sugar conversion process, combined with temperature and atmospheric pressure changes, creates a pressure gradient that causes the sap to flow out of the tree through tap holes or wounds.

Maple syrup sap has a relatively low sugar content compared to the final product. On average, maple sap contains around 2-3% sugar. The primary sugar present in the sap is sucrose, along with smaller amounts of glucose and fructose. The sap also contains various minerals, trace elements, organic acids, and amino acids.

To produce maple syrup, the sap is collected from the trees and then undergoes a process of evaporation. This concentrates the sugars and flavors in the sap, transforming it into the thick, sweet maple syrup we enjoy. It typically takes a significant amount of sap, often 40 liters or more, to produce a smaller amount of maple syrup due to the high water content in the sap.

What is the difference between Maple Syrup and Sap?

Maple syrup and maple sap are distinct in composition, characteristics, and culinary uses. Here are the key differences between the two:

- Composition: Maple sap is the raw liquid extracted directly from maple trees. It is a clear and watery fluid that primarily consists of water, with a relatively low sugar content ranging from 2% to 3%. On the other hand, maple syrup is the concentrated and processed form of maple sap. It undergoes evaporation to remove a significant portion of the water, resulting in a thick and sweet syrup. Maple syrup typically contains around 66-67% sugar, contributing to its rich and distinct flavor.

- Flavor and Sweetness: Maple sap has a mild and subtle taste, with a hint of sweetness due to its natural sugar content. However, the sugar level must be concentrated enough to provide the intense maple flavor associated with maple syrup. In contrast, maple syrup boasts a robust and distinctive flavor profile characterized by its rich caramelized notes and natural sweetness. The evaporation process concentrates the sugars and flavors in the sap, resulting in a characteristic taste that is highly sought after.

- Culinary Uses: Maple sap is not commonly consumed as a standalone product due to its low sugar content and mild flavor. It is primarily used as the base for producing maple syrup. On the other hand, maple syrup is a popular and versatile natural sweetener used in a wide range of culinary applications. It is commonly drizzled over pancakes, waffles, and French toast, used as a topping for desserts, added to beverages, incorporated into glazes or marinades, and used in various recipes to impart its distinct flavor.

- Production Process: Maple sap is collected by tapping maple trees and allowing the sap to flow into collection containers. It is then transported to a sugarhouse or processing facility for further processing. Maple syrup production involves the evaporation of the sap to remove water content and concentrate the sugars. This process typically occurs in specialized evaporators using heat sources like wood, fuel burners, or electric elements.

In summary, maple sap is the raw liquid extracted from maple trees, while maple syrup is the sap’s concentrated and processed form. Maple syrup has a higher sugar content, a distinctive flavor profile, and a wide range of culinary uses compared to sap.

What is the Process of Evaporation of Maple Syrup?

Evaporating maple syrup involves heating and boiling the sap collected from maple trees to remove the water content, leaving behind the concentrated syrup. Here is a step-by-step explanation of the process:

- Sap Collection: Maple trees are tapped by drilling a small hole into the trunk, and a spout or tap is inserted to allow the sap to flow out. The sap starts flowing in late winter or early spring when the weather conditions are favorable.

- Sap Transportation: The sap is collected in buckets or through tubing systems connected to the taps. It is then transported to the sugarhouse or processing facility for further processing.

- Filtration: Once the sap is collected, it undergoes filtration to remove any impurities or debris. This ensures a cleaner and higher quality end product. The sap may pass through mesh filters or reverse osmosis systems.

- Preheating: After filtration, the sap is preheated to raise its temperature before it enters the evaporator. Preheating helps speed up evaporation and reduces the time required to produce maple syrup.

- Evaporation in the Evaporator: The preheated sap is transferred to the maple syrup evaporator. The evaporator consists of shallow pans or channels placed over a heat source, typically a wood fire or fuel burner. The sap flows through the evaporator pans, and the heat underneath causes the water in the sap to evaporate. As the water evaporates, the sap becomes more concentrated.

- Multiple Compartments: The evaporator pans are divided into compartments, each heated to a higher temperature. The sap flows from one compartment to another, gradually thickening and concentrating as it moves through the evaporator. This ensures efficient evaporation and concentration of the sap.

- Density Testing: Throughout the evaporation process, the density or sugar content of the sap is monitored. This is typically done using a hydrometer or refractometer. The goal is to reach the desired density for maple syrup.

- Finishing: Once the sap reaches the desired sugar concentration, it is transferred to a finishing pan. The final stages of evaporation take place in the finishing pan, ensuring that the syrup has the perfect consistency and flavor.

- Filtering: After the syrup reaches the desired density, it undergoes another filtration process to remove any remaining impurities. This helps achieve a smooth and precise finished product.

- Packaging: The finished maple syrup is packaged in containers, such as bottles or cans, ready to be enjoyed on pancakes, waffles, or other dishes.

It’s important to note that the exact process may vary depending on the specific equipment and techniques maple syrup producers use. However, the overall goal remains: to evaporate the water from the sap and transform it into delicious maple syrup.

What are the Different Types of Maple Syrup Evaporators?

Different types of maple syrup evaporators are available, each with unique characteristics and advantages. Here are some of the common types:

- Traditional Wood-Fired Evaporators: These evaporators use wood as the primary heat source. Conventional maple syrup producers often prefer them for their authentic and classic feel. Wood-fired evaporators require manual wood feeding and careful fire monitoring to maintain consistent heat levels.

- Fuel Burner Evaporators: Fuel burner evaporators use propane or natural gas to heat the pans. They offer convenience and ease of use, as they can be controlled and regulated. Fuel burner evaporators are popular among commercial maple syrup producers due to their efficiency and ability to provide consistent heat.

- Electric Evaporators: Electric evaporators are powered by electricity, making them a convenient and easy-to-use option. They eliminate the need for manual fuel feeding and produce less smoke compared to wood-fired evaporators. Electric evaporators are often preferred by smaller-scale maple syrup producers or those who have restrictions on using wood or fuel burners.

- Hybrid Evaporators: Hybrid evaporators combine multiple fuel sources to provide flexibility and efficiency. They can utilize a combination of wood, fuel burners, or electric elements, allowing producers to choose the most suitable option for their needs. Hybrid evaporators offer versatility and the ability to adapt to different fuel availability or preferences.

- Steam Evaporators: Steam evaporators utilize steam from an external boiler to heat the sap. The steam is circulated through a series of pipes or pans to evaporate the water content. Steam evaporators are often used in larger-scale commercial operations where a separate boiler system is available.

Notably, maple syrup evaporators come in various sizes and configurations to accommodate different production scales, from hobbyist or home use to large-scale commercial operations. The choice of evaporator type depends on factors such as production volume, available fuel sources, personal preference, and budget considerations.

What are the Benefits of Maple Sap?

Maple sap offers several benefits, both nutritional and otherwise. While it is less commonly consumed independently, it still possesses certain advantages. Here are some of the benefits of maple sap:

- Hydration: Maple sap is primarily composed of water, making it a hydrating beverage. Staying adequately hydrated is essential for maintaining overall health and supporting various bodily functions.

- Natural Minerals: Maple sap contains various minerals that are beneficial for the body. These minerals include calcium, potassium, manganese, magnesium, and zinc. These minerals support bone health, muscle function, nerve function, and enzyme activity.

- Antioxidants: Maple sap contains antioxidants, which help combat free radicals in the body. Free radicals are unstable molecules that can cause oxidative stress and damage cells. Antioxidants help neutralize these harmful molecules, reducing the risk of chronic diseases and supporting overall health.

- Electrolytes: Maple sap naturally contains electrolytes such as potassium and magnesium. These electrolytes are essential for maintaining fluid balance, supporting nerve function, and regulating muscle contractions.

- Natural Sweetness: While maple sap has a mild sweetness, it can still be used as a natural alternative to plain water or sugary beverages. It provides a subtle hint of sweetness without adding sugars or artificial sweeteners.

- Traditional and Cultural Significance: Maple sap holds cultural and traditional significance in regions where maple syrup production is prominent, such as parts of North America. It is often celebrated as a symbol of local heritage and a connection to nature.

It’s important to note that the concentration of these benefits is significantly higher in maple syrup, as the sap is boiled down to produce syrup. Maple syrup offers a more concentrated source of nutrients, including antioxidants and minerals.

While maple sap can be enjoyed on its own, its primary use lies in its transformation into maple syrup through the evaporation process. This process enhances the flavors and concentrates the beneficial components found in the sap.

As with any food or beverage, it’s recommended to consume maple sap or maple syrup in moderation as part of a balanced diet.

Homemade Maple Syrup Evaporator

Creating a homemade maple syrup evaporator can be a rewarding project for maple syrup enthusiasts. While commercial evaporators offer efficiency and convenience, building your setup allows for customization and a hands-on experience. Here’s a general overview of the process of constructing a primary homemade maple syrup evaporator:

- Design and Planning: Determine the size and configuration of your evaporator based on the amount of sap you plan to process. Consider factors such as available space, budget, and the materials you can access. Research different evaporator designs and gather ideas to create a blueprint or plan.

- Materials and Tools: Gather the necessary materials and tools for construction. The specific requirements will depend on your chosen design. Still, common materials include stainless steel or galvanized steel pans, firebricks or cinder blocks for support, a heat source (such as a propane burner or wood fire), piping or channels for sap flow, and a chimney or exhaust system.

- Pan Configuration: Construct the evaporator pan or pans according to your design. Weld or join the stainless steel or galvanized steel sheets to create a durable pan that can withstand high heat. Ensure proper dimensions and consider adding compartments or dividers to regulate the sap flow and promote efficient evaporation.

- Support Structure: Build a sturdy support structure to hold the pans. This can be done using firebricks or cinder blocks arranged in a manner that supports the weight of the pans and allows for the fire or heat source to be positioned underneath. Ensure the structure is stable and level.

- Heat Source: Determine the type of heat source you will use, whether it’s a propane burner or a wood fire. If using a propane burner, ensure it is adequately regulated and safely connected to a propane tank. If using a wood fire, create a designated area for the fire and consider installing a grate or grate system to hold the wood and promote efficient burning.

- Sap Flow: Establish a system for sap flow from the collection container to the evaporator pans. This can be achieved using gravity or incorporating pipes or channels to direct the sap flow. Ensure the sap flow is controlled and evenly distributed across the pans.

- Testing and Modifications: Once your homemade evaporator is constructed, test it with a small amount of sap to ensure it functions properly. Make any necessary adjustments or modifications to improve efficiency and performance.

- Safety Precautions: It’s crucial to prioritize safety during the construction and operation of your homemade evaporator. Follow safety guidelines for the chosen heat source, ensure proper ventilation and fire safety measures, and use protective gear when necessary.

Remember that constructing a homemade evaporator requires technical skills and knowledge of heat sources. If you are not experienced in these areas, it is advisable to seek guidance from experts or consider purchasing a pre-made evaporator. Safety should always be the top priority when working with heat and fire.

Building a homemade maple syrup evaporator can be a fulfilling project that allows you to engage with the maple syrup production process on a deeper level. Enjoy the process and the sweet rewards of your homemade maple syrup.

FAQs about Maple Syrup Evaporators

Q1. How long does making maple syrup using an evaporator take?

Ans. The time required to make maple syrup can vary depending on several factors, including the sugar content of the sap, the size of the evaporator, and the efficiency of the equipment. It takes approximately 40 liters of sap and 30-40 hours of boiling to produce one liter of maple syrup.

Q2. Can maple syrup evaporators be used for home production?

Ans. Maple syrup evaporators come in various sizes, including smaller models suitable for home or hobbyist production. However, it’s important to note that making maple syrup can be time-consuming and requires careful attention to detail.

Q3. Are there different types of maple syrup evaporators?

Ans. Yes, different types of maple syrup evaporators are available, ranging from traditional wood-fired evaporators to more modern fuel burners or electric models. Each type has its advantages and considerations, depending on the scale and preferences of the syrup producer.

Q4. Can maple syrup evaporators be used for other purposes?

Ans. Maple syrup evaporators are primarily designed for maple syrup production. However, they can also be used for other purposes, such as evaporating other liquids or general cooking applications requiring a large surface area and controlled heating.

Q5. How long do maple syrup evaporators last?

Ans. The lifespan of a maple syrup evaporator depends on various factors, including the quality of the equipment, maintenance practices, and frequency of use. Well-maintained evaporators can last for several decades, providing many years of reliable service.

Q6. Where can I purchase a maple syrup evaporator?

Ans. Maple syrup evaporators can be purchased from specialized maple equipment suppliers, agricultural supply stores, or online retailers. It’s essential to choose a reputable supplier that offers high-quality equipment.

Conclusion:

Maple syrup production is a labor of love that requires skill, patience, and a deep appreciation for nature’s sweet gift. The maple syrup evaporator plays a vital role in transforming maple sap into the golden elixir we cherish. From tapping the trees to boiling down the sap, each step in the journey contributes to creating a truly exceptional product. So the next time you enjoy a stack of pancakes drenched in maple syrup, take a moment to savor the flavors and remember the remarkable journey from tree to table.

Related Articles:

How to Install an Off Grid Outdoor Shower?